A Guide to RJC Sensors

Everything you need to know about fiber optic sensor products

How Our Sensors Work

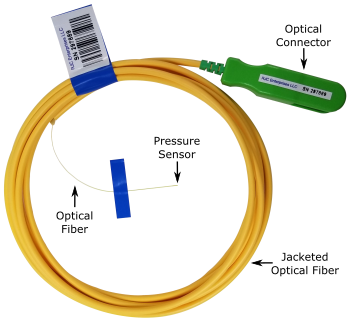

RJC Sensors are based on the Fabry-Perot interferometer, in which two minimally separated, partially reflecting surfaces form an optical reflecting cavity. If one of these surfaces is a pressure sensitive diaphragm, changes in external pressure cause a change in depth of the optical reflecting cavity, which in turn alters optical cavity reflectance spectra. For Temperature, the band edge in a special filter glass changes with temperature, and this shift is proportional to temperature change.

Our instrumentation (for pressure and temperature) contains an 850 nm LED whose emissions reach the sensor via an optical fiber. In the sensor’s optical reflecting cavity, the spectral distribution of LED light is modified as a function of cavity depth, and this spectrally altered light is reflected back down the fiber to the instrument. Light returning to the instrument is optically split into two spectral components; the photocurrents from these two components form a ratiometric signal which in turn correlates with changes in the measured parameter. For pressure measurements, differential pressure is obtained by referencing an internal solid state barometric transducer.

The Oxygen Sensor (under development) consists of a luminescent compound in a polymer matrix applied to the sensing end of an optical fiber. The phosphorescence decay time of the compound is dependent on the oxygen concentration at the sensor location. A green light source is briefly turned on to induce phosphorescence in the compound. The green light source is then turned off and the decay time is measured. This decay time is used to calculate the oxygen concentration at the sensor.

Fiber Optics vs. MEMS vs. Piezoelectric

There are many ways to measure pressure, temperature, oxygen, etc. on a small scale. The three primary methods are with fiber optic sensors, microelectromechanical systems (MEMS), and piezoelectric sensors. There are positives and negatives to each kind of sensor, and further variation depending on the quality of sensor construction.

» Fiber optic sensors use light transmitted through optical fiber to detect changes in pressure, temperature, and other physical properties. With pressure, for example, a microscopic membrane at the end of the sensor flexes according to stress and modifies returning light that is read by a highly-accurate instrument.

» MEMS/Electromechanical sensors use miniature mechanical structures and electrical components to measure forces such as acceleration, pressure, or strain. These sensors are widely used in consumer electronics, automotive systems, and industrial applications. They are best for economical applications that require less accuracy, resilience, and durability.

» Piezoelectric sensors generate an electrical charge in response to mechanical stress, making them well-suited for dynamic measurements such as vibration monitoring and acoustic sensing.

Sensitivity and Accuracy

Fiber Optic Sensors: Highly sensitive to small changes in temperature, pressure, and strain, making them ideal for high-precision applications like medicine, structural health monitoring, and oil and gas exploration.

MEMS/Electromechanical Sensors: Offer good sensitivity and fast response times, but can suffer from drift and require periodic recalibration, especially in high-vibration environments.

Piezoelectric Sensors: Highly responsive to dynamic changes but may experience signal degradation over time and are less suited for static measurements.

Environmental Resistance

Fiber Optic Sensors: Immune to electromagnetic interference (EMI) and resistant to harsh environments, including high temperatures, high pressures, and corrosive conditions. As a result of EMI immunity, fiber optic sensors are inherently MRI-compatible, making them ideal for use in medical imaging and diagnostics, or in situations where imaging may become necessary (e.g., long-term intra-cranial pressure monitoring).

MEMS/Electromechanical Sensors: Sensitive to EMI and mechanical vibrations, which may impact performance in certain environments.

Piezoelectric Sensors: Can degrade under extreme temperatures and humidity, limiting their lifespan in harsh conditions.

Installation and Maintenance

Fiber Optic Sensors: Lightweight and flexible; can be embedded in instruments with minimal maintenance and extremely infrequent need for re-zeroing.

MEMS/Electromechanical Sensors: Compact and easy to integrate but may require recalibration and regular re-zeroing, the latter of which necessitates a neutral environment (e.g., removing the sensor from a patient to re-zero it).

Piezoelectric Sensors: Moderate installation complexity with some degradation over time, requiring occasional maintenance.

Longevity and Durability

Fiber Optic Sensors: Made of glass or polymer materials that do not degrade over time, ensuring long operational life; collision-resistant with a highly bendable fiber.

Come visit us to experience the durability of glass fibers firsthand as we tie them into knots.

MEMS/Electromechanical Sensors: Can experience wear and contamination, particularly in high-dust or high-moisture environments. Vibrations and collisions can damage the sensor.

Piezoelectric Sensors: Material properties can deteriorate after repeated stress cycles, affecting long-term performance.

Cost Efficiency Over Time

Fiber Optic Sensors: If you plan on using sensors more than once, fiber optic can have a higher initial cost but lower long-term maintenance and replacement cost due to durability.

MEMS/Electromechanical Sensors: Typically cost-effective upfront but may require more frequent recalibration or replacement, increasing long-term costs.

Piezoelectric Sensors: Moderate cost but may need periodic replacement due to material degradation.

Why Fiber Optic Sensors Often Lead the Way

Each sensor type has its own set of advantages and is best suited for specific applications. However, for industries requiring high precision, reliability, and resilience, fiber optic sensors often provide the best long-term solution. Their immunity to electromagnetic interference, resistance to harsh environments, minimal maintenance, and long lifespan make them highly applicable to aerospace, oil and gas, civil infrastructure, and medicine.

If you’re looking for a sensor solution that balances accuracy, durability, and cost efficiency, fiber optic sensors are a leading option. Contact us to have a conversation about how our fiber optic sensors might be beneficial to you.

Are RJC Fiber Optic Sensors For You?

There are lots of factors to consider when picking the right sensor. That’s why we’ve assembled a comprehensive guide.

To help you decide, here’s a quick set of guidelines:

- Do you require very small sensor size?

- Do you require high performance (i.e., frequency response, accuracy, stability, etc.)?

- Do you require a rugged/durable sensor?

- Do you require immunity from electrical and magnetic noise?

If you answered YES to one or more of these questions, then RJC fiber optic sensors may be right for you.

Size

Nearly microscopic sensors

With RJC sensors, you can reach some of the most confined areas of the body.

Our sensors are built for the stringent demands of catheters and guide wires, where every micron counts. We are acutely aware that the goal of every invasive procedure is to be as minimally invasive as possible. That’s why we offer sensors of different sizes, and also why we reinvest so much of our profits into research and development. We want to make the smallest sensor possible.

Currently, our smallest sensor is only 246 microns in diameter, which is just 76 microns larger than the fiber it sits on. That means you could fit 6 of them side by side inside a 5-French catheter!

Ease of Use

Quick to learn for manufacturers and clinicians

RJC sensors are plug-and-play. There is never a need for manual data entry because calibration is loaded automatically. No calibration data is ever manually entered by anyone, including us. Sensors are zeroed when they are first inserted–so there’s no need for a Zero button–and implanted sensors that are reinserted into the same instrument will remember their previous zero.

RJC instrumentation is designed to work in any system. The Model 601, for instance, natively supports analog output, a patient monitor, USB type B, and a flash drive for logging data. Our basic assemblies, like the Model 500, is designed to interface seamlessly with a customer’s propriety device.

We work closely with each customer to ensure they understand how our systems can be best utilized. That includes working with both hardware and software teams to integrate RJC sensors and instrumentation. Every instrument/sensor kit comes with installable software for sensor data display and logging.

Materials and Durability

Rugged Components Built to Last

Glass fibers are coated in a polyimide buffer and surrounded with strain relief fibers made of Kevlar that protect against stretching. All of that is jacketed in flexible PVC.

This means that our sensor assemblies remain protected and fully operational in rugged clinical environments. The assemblies will remain accurate with bending up to a radius of ~2.5mm. Even then, extremely tight bends would be necessary to permanently damage the fiber.

Why We Use Glass Fibers and Why You Should Too

RJC Sensors are mounted on highly flexible glass fibers, which means you get corrosion-resistant, rugged sensors with higher information transmission capacity and lower loss.

Glass fibers are generally preferred over plastic fibers due to several critical advantages.

First, glass fibers offer significantly lower optical attenuation compared to plastic fibers. Light signals traveling through glass fibers experience less degradation, enabling signals to maintain integrity over longer distances. Lower attenuation directly contributes to enhanced sensitivity and accuracy in sensor readings, which is particularly important in demanding sensing applications.

Second, glass fibers have superior temperature resistance compared to plastic fibers. While plastic fibers generally begin to degrade at relatively low temperatures (sometimes around 70–85°C), glass fibers can comfortably withstand temperatures of several hundred degrees Celsius without significant performance loss. This makes glass fibers far better suited to applications involving harsh or extreme thermal environments, such as industrial process control, aerospace applications, and structural health monitoring in demanding conditions.

Third, glass fibers offer enhanced chemical and mechanical durability. Plastic fibers are susceptible to chemical damage, abrasion, and physical deformation, compromising their reliability in harsh environments. In contrast, glass fibers exhibit strong resistance to chemicals, abrasion, humidity, and mechanical stress, providing consistent and reliable performance even in corrosive or mechanically demanding settings.

Fourth, the signal precision and stability offered by glass fibers outperform that of plastic fibers significantly. Glass fibers have lower thermal expansion and improved dimensional stability, resulting in more accurate, stable, and repeatable sensor measurements. For precision-oriented sensing applications—such as medical diagnostics, structural monitoring, and scientific research—this level of accuracy and stability is essential.

Lastly, glass fibers provide broader spectral transmission ranges, making them suitable for use with a wider variety of wavelengths. This versatility enables more specialized sensor technologies, such as those leveraging infrared wavelengths or advanced interrogation methods (like wavelength division multiplexing), enhancing flexibility and expanding possible applications. Despite this versatility, RJC uses very narrow criteria when selecting our specialized LEDs because we want to make the best instruments possible.

Cost

High-end products at affordable prices

Fiber optics tend to be more expensive than their sensing counterparts. There’s no way around it. So why do so many companies still use fiber optic sensors? The answer is that fiber optics tend to beat out MEMS and piezoelectric systems in every other metric.

This is one of the reasons we are so flexible about our product lines. RJC wants to ensure that our sensors and instrumentation work perfectly for each customer at the most affordable price possible.

Many medical products employing sensing functions are designed for single use. Fiber optic sensors can—particularly in the case of pressure and temperature sensors—cost more than traditional semiconductor-based sensors, in part because optical fiber costs more than wire, and optical connectors costs more than electrical connectors.

However, for other types of sensing, such as oxygen sensing, the cost of a fiber optic sensor may be less than traditional oxygen sensor technologies. If you are interested in a fiber optic oxygen sensor, contact us.